Home – Contact Us Visit our sister company Standard Metal Industries |

PRICE SHEETS: |

| - 45° Weld Ells |

| - 90° Weld Elbows |

| - Screwed 90° Ells & Socket Ells |

FOR CUSTOMER SERVICE & ORDER PLACEMENT CALL: |

ICA Mineral Wool 1200° ICA M.W. 1200° Hi-Temp Pipe Insulators - ASBESTOS FREE! |

|||||||||||||||||||

| Dual-Temperature, Premolded, Top Quality, Two-Pieced Thermal-Acoustical Pipe Fitting Insulators TECHNICAL DATA The ICA M.W. 1200° is a unique product in the realm of high-temperature preformed insulation for pipe fitting areas. The ICA M.W. 1200° pipe fitting insulator is serviceable to 1200°F and was designed to be utilized in conjunction with any high temperature straight-run insulation of equal surface temperature capabilities. ICA M.W. 1200° pipe fitting insulators have been employed successfully in mineral wool, calcium silicate, and expanded perlite systems. ICA's molding process yields a fitting insulator which is completely different from the routed fitting insulators which have been extensively marketed in the past. In a routed insulator the finished product is cut from a section of block insulation with comprising fibers being oriented in a single direction, hence, extreme fragility in the finished product. In contrast, the ICA product is molded under extreme heat and pressure from uncured green felt which is impregnated with a thermo-setting resin. Thus the ICA M.W. 1200° fitting insulator is composed of fibers that are interbonded and intermeshed in many different directions; the resulting strength means that the ICA insulation cover can be and is produced in fitting sizes never before realized. |

|

||||||||||||||||||

Unlike a routed insulator, the ICA fitting insulator will not readily delaminate. When coating of the fitting's exterior surface is desired or required, fibers will not dust or fuzz up. This remarkably durable insulator exhibits superior load-bearing characteristics when compared to previous applications, for fitting areas. Extensive on-the-job loss due to breakage is a thing of the past.The ICA M.W. 1200° is actually strong enough to be utilized on line, removed for inspection or maintenance purposes. and utilized once again. ICA M.W. 1200° pipe fitting insulator are molded in two half sections, matching the density and thickness standards of the adjoining pipe covering. All fitting insulators are currently manufactured in weld, screwed, socket, and copper tubing types; all in 90° and 45° and tee configurations. For pipe sized presently unavailable and for further speciality application requirements, consult with ICA's Research and Development Department regarding our design and engineering capabilities.

APPLICATIONS: Benefits of using pre-formed ICA M.W. 1200° High temperature fitting covers:

AVAILABILITY CHART

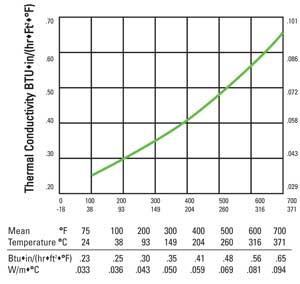

*Larger T's up to 12" available in the near future. Thermal Conductivity ("k")

Thermal conductivity and physical properties based on unfaced mineral wool fittings. Technical data as supplied by Eagle-Pitcher. |

|||||||||||||||||||

Specification Compliance: |

MIL Specifications MIL-22344-B MIL-24244-B* Specifications Federal Specifications HH-I-558B, Type III, Form E, Class 17 |

||||||||||||||||||

*Please contact ICA Headquarters before order placement, refernce compliance to NRC reg. guide 1.36 and MIL-24244B for special handling.

|

|||||||||||||||||||

Copyright 2018 ICA Insulation Site by Fringe Marketing